Keywords:

Spin flash dryer, Vacuum dryer, Spray drying granulator, Efficient grinder, Double tapered nixer, Vibrating screen, Stove, Dust collector

General Manager: Bo Jijun

Address: Changzhou City, Jiangsu Province Cheng Town jiaoxi

Tel: 0086-519-88901234 88905678

Fax: 0086-519-88900668

Post Code: 213116

E-mail: bojijun@aliyun.com

product description

This can be done while the unit is a drying and granulating device. According to process requirements can adjust the feed pump pressure, flow rate, the size of the orifice, and the desired size by a certain proportion of spherical particles.

The operation of this unit for the feed solution through the diaphragm high-voltage input, discharge or mist, and then decreased with the flow of hot air, most of the separated particles collected from the bottom discharge opening, exhaust and fine powder by cyclone exhaust gas discharged from the exhaust fan, the powder is provided in the lower end of the cyclone collection tube pollination, fan outlet can also be equipped with two dust removal device, and the recovery of more than 96-98%.

The unit tower in contact with the material part of the pipeline, separator material, are used SUS304 production. Between the tower and the interior of the housing there is sufficient moisture barrier filler material is ultra-fine glass wool, with observation tower doors, mirrors, lighting and control instruments, electrical control by the console control and display.

Applications

Pharmaceutical industry: tablets, granules, capsules, granules; sugar, sugar-free particles of medicine; food: cocoa, coffee, milk powder, granule juice, spices; Other industries: pesticides, feed, fertilizer, pigments, dyes and the like.

Product Features

1, fast-drying, greatly increasing the surface area of the material after the liquid is atomized in a stream of hot air, you can instantly evaporate 95% -98% of water to complete the drying time only need ten seconds to tens of seconds species, particularly suitable for drying heat sensitive materials.

2, all products of spherical particles, uniform size, good mobility, good solubility, high purity and good quality.

3, using a wide range, depending on the characteristics of the material can be dried with hot air, it can also be used cold granulation, strong adaptability of the materials.

4, simple operation and stable, easy to control, easy to automate operations.

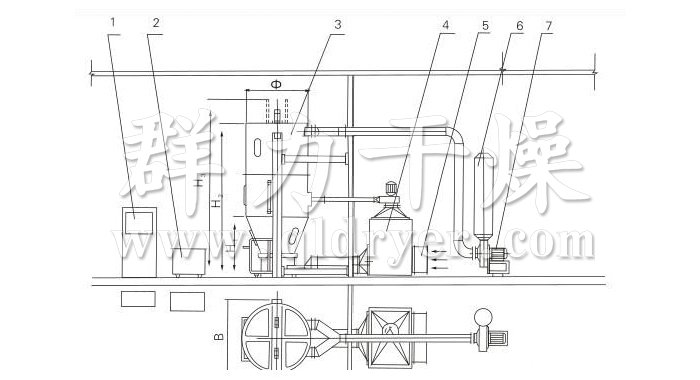

Schematic

1, 2 control cabinet, infusion car 3, the host 4, 5 heat exchanger cabinet, sub-efficient filter 6, muffler 7, Fan

Technical Parameters

| Items | Unit / Aircraft | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

| Liquid extract | Least | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

| Maximum | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

| Boiling capacity | Maximum | kg/批 | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| Maximum | kg/批 | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| Hydrometer | kg/L | ≤1.30 | |||||||

| The amount of raw container | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| Vessel Diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| Induced draft fan power | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

| Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| Steam | Consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| Pressure | MPa | 0.40-0.60 | |||||||

| Electric type power | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

| Compressed air | Consumption | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

| Pressure | MPa | 0.40-0.60 | |||||||

| Operating temperature | °C | Automatically adjust the room temperature -160 ° C | |||||||

| Product moisture | % | ≥0.2 | |||||||

| Material yield | % | ≥99 | |||||||

| Equipment noise | dB | <77 | |||||||

| Host size | Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

| H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

| H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

| H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

Selection of cases: requirements per batch stream extract amount I = 120kg (solid content of 30%), the amount of seed II = 60kg, can I, II theorize finished quantity M = mI + mII = 120kgx30% + 60kg = 96kg, working time T = 120kg / 30kg / h = 4h, the technical parameters bar can find out boiling the amount of the standard load range, so as to complete the class two batches, the choice of PGL-30 type is more appropriate.

Changzhou Qunli Drying Equipment Co., Ltd. is a professional design and manufacturing expertise drying, mixing, granulating and other equipment, is located in China's most economically developed Yangtze River Delta - a "dry town" Coke Town, thanks to the surrounding sound industrial base and advanced machinery manufacturing industry, and their own strong technical force.